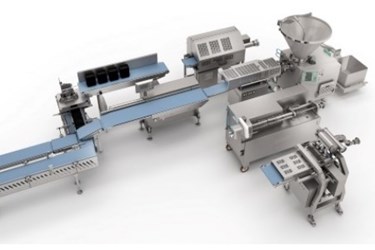

Flexible Fresh Meat Line - Different Attachments For All Applications On A Line

The need to have several lines for production of different products is now a thing of the past. Innovative production possibilities can be achieved by simply exchanging attachments with the same length in the existing line. The savings are impressive: for instance, instead of four lines previously, there is now only one - reducing space requirements to a minimum.

The flexible fresh meat line allows the production of different products on a single line. It consists of three sections. The vacuum filler with separation grinder as well as the loading system are fixed in position. Attachments have the same length and are interchangeable. They are suitable for the production of burgers, Adana Köfte (Turkish ground lamb meatballs) minced meat, cevapcici, fresh grilling sausages, meatballs, and many other specialties.

The interchangeable attachments include:

Forming Machine FM250:

The products coming from the forming machine are characterized by an exceptional texture and bite. The meat fibers in the finished product retain their natural alignment, so that the final product has the texture of a handmade specialty.

Minced Meat Portioner MMP220:

The minced meat portioner is suitable for producing minced meat from beef, pork or poultry. The shape of the product can be adjusted easily to different tray sizes.

Ball Control BC236:

The ball control BC236 is a universally applicable machine used for producing convenience products. These can be filled with a single product or, following an expansion, by means of coextrusion. Whether it's meatballs and croquettes, cheese balls with a fruit filling or chopped steak with feta - this is where you create your products for your customers: fast, cost-effectively and within exact shape and weight.

Flexible Sausage Line FSL210

The FSL210 is a machine offering flexible and accurate length portioning, linking and separating of sausages in natural and collagen casings.

Anyone who has already operated a vacuum filler will also be able to operate this flexible line. Intuitive. The entire line is controlled solely by the filler.

Like all VEMAG machines and attachments, this flexible line can be cleaned with low-pressure equipment and commercially available cleaning agents.

The loading system switches to the stored packaging type depending on the specialty being produced. A shuttle conveyor places minced meat, burgers and cevapcici into trays automatically and transports them on for further processing - on request, the products can be stacked, overlapped or arranged next to one another in the trays.

Sausages and meatballs are placed in the trays by hand, with the trays presented to the operator in accordance with the production speed.

Source: VEMAG MASCHINENBAU GMBH